Graduating Bentley University with a Degree in Computer Information Systems, I knew I always was interested in technology and how it could improve our lives. I felt that just a technology degree was not enough, and went back in for a Master's Degree at Bentley which would help me better understand a businesses needs and priorities.

Starting my career early on, I implemented an early version on an ERP system at a small manufacturing company. Since it was a small company, I was also involved in putting together the financials and closing the fiscal months. From there, programmed in Foxpro prior to moving to GE as a Business Analyst during the .com days where the goal was to put everything on a computer. I overlapped into a more technical role there as one of the data collection applications was poorly designed and needed to be rewritten from the ground up.

From there, I migrated to an Inventory position helping to define and communicate the KPI's around inventory to the Power Business at GE. A key part of the inventory position was that my boss was also the Lean Leader for GE Energy where we traveled to many of the locations hosting lean events which were used to remove waste, but also to help train the locations on some of the Lean practices. This naturally fed me into a role to be the Functional Track Lead for the Oracle implementation for the Wind Energy Business. After the Wind implementation, I transitioned to the Oil and Gas division where I managed a planning department, and also worked on another Major Oracle implementation.

Next, I left GE to work at Exterran where I managed the planning department improving the OTD to near 100% from in 35% by effectively managing the ERP system to provide the right visibility to the business. The compression division was then sold to Compass where I defined processes and data elements to align to the business needs using Microsoft NAV. I then formalized some of the data required to run the business into Power BI, which involved some complex SQL queries in the back end.

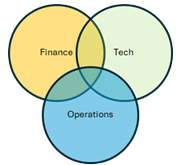

Get to know me by reading through some of these pages. I tried to break down my technology background to give an idea of what I have done as well as the supply chain to see where the two might overlap. I have not included a section on Finance, but in addition to doing some programming projects on the side, I am an avid investor and enjoy analyzing balance sheets, income statements and cash flows of various companies and industries.

Relevant Degrees

Years expERIENCE

ERP implementations

Languages (computer)